F&P "Combo" Lines (New), 1500x2mm/5ton #4945

F&P "Combo" Lines (New), 1500x2mm/5ton #4945

Description

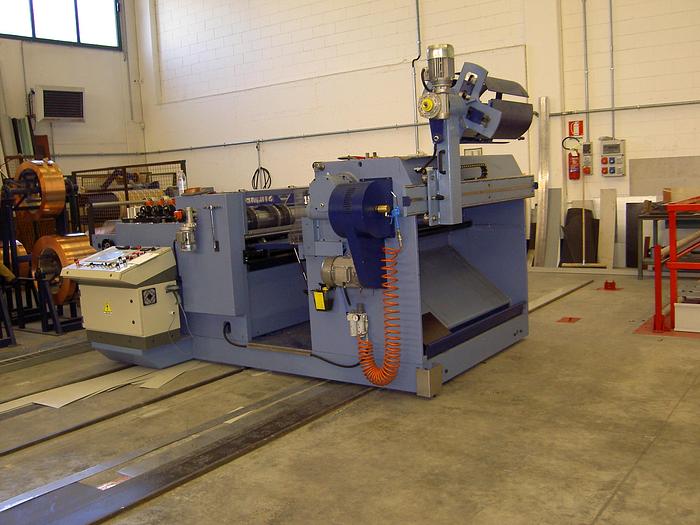

Line speed at slitting-recoiling: up to approx. 30m / minute with loop pit; 20+m / minute, max., if few longitudinal cuts and rather "wide" strips -- or less if several cuts, with no loop pit

These lines can be used either for single-/multi-blanking (possibly with the insertion of a sheet stacker, to be studied and quoted on specific information) or, for slitting-and-recoiling. At the customer's choice, they can work with or without loop pit ^

+ There are several options available for them (in-line punching, marking, etc. equipment; simultaneous blanking and, respectively slitting-rewinding of different areas of the coil...) as shown in the Attachment at the bottom of the text

> Max. material thickness (M.S.) at blanking: 2.0mm

> Max. material thickness (M.S.) at slitting: 1.5mm

Description

5ton powered decoiler with 3-segment mandrel drum, hydraulically operated expansion (470-540mm) by wedges

RPM: 16

- hydraulic coil loading car with max. stroke 1800mm optional

- unmotorized snubber arm optional

other options:

- "overtiles"

- D.C. motor driven paper winder

or

- unpowered decoiler/s

-- Max. Coil OD 1560mm

2 chromium plated, dia. 50mm entry rolls and two guides: one fixed, the other mobile adjustable by a handwheel connected to a tapezoidal worm screw

two oilproof rubber coated, dia. 134mm pinch rolls: the upper roll mounted on eccentric supports, adjustable by a handwheel

straightener with 7, dia. 105mm chromium plated and ground rolls: the three upper rolls supported by vertical prismatic skates with screw-transmission, adjustable by handwheel and equipped with a position readout instrument (centesimal accuracy)

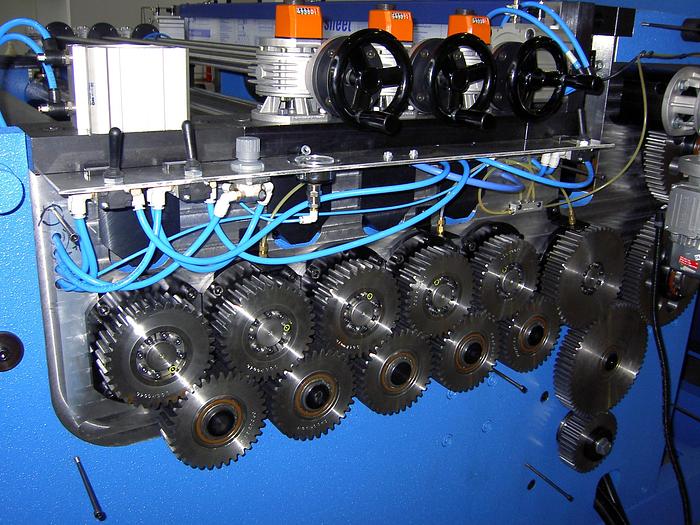

dia. 140mm shaft slitter with 3 pairs of quick-clamping circular knives as "standard". Both shafts motorised; the upper shaft mounted on eccentric supports with stop

overturnable loop pit overtaking table optional - if loop pit wanted

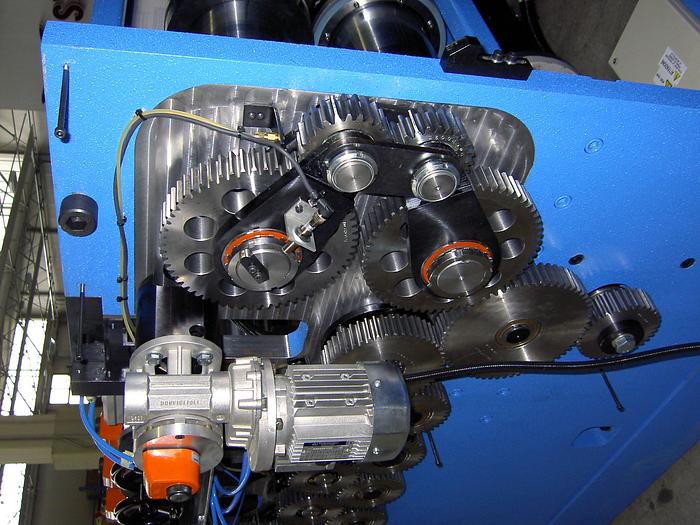

mech. power guillotine shear with brushless motor drive, electro-pneumatic brake/clutch, transmission by gears, centralized lubrication system, adjustment of blade clearance by micrometric screws. Allsteel blankholder, upper blade holder sliding on guides adjustable from the outside; blades with two cutting edges, treated to also cut stainless steel

strip tension pad with air operated mobile upper head, easy to replace felt

recoiler with overarm and coil ejection plate, hydraulically operated expansion (480-508mm) by wedges

- hydraulic coil off-loading car with max. stroke 1500mm optional

Other options:

- strip separators

- (if loop pit wanted) quadrant rolls for loop pit, pneumatic pit cover board

all electrics and pneumatics

hydraulic componentry by Bosch Rexroth and other primary Brands

other options available:

- material entry auto.- damper, air operated ( helpful when using unpowered decoiler/s ^)

- motorized material entry guide (operated by pushbutton or programmable)

- material entry table (which raises and lowers, manually)

- auto.-lifting/lowering of the straightener rolls

- PVC film applicator

- marking system for the fold line

- blanking/notching/punching... units (up to 18) with digital readouts

- hydraulic C-frame press with powered transverse displacement (particularly for producing front elements of ventilated roofs)

- additional pairs of circular knives, generaly up to max. 7 pairs in total

- auto. lifting/lowering of slitter knives

- automatic search system for the slitting knife position (the fixing of the tooling is then manual)

- 50kg, 3-30mm scrap winder

- 150kg, mini-recoiler with 600mm mandrel drum for large scrap -- alternative to the 5ton recoiler

- loop pit equipment, custom designed (the pit, optional, is 2x4m and 4m deep)

- sheet stacker, custom designed

- powered translation system, placed on a single platform for all the equipment excluding stock reel/s & coil cars

- radio-controller for remote control of the line

sound damping equipment (normally not necessary) and peripheral safety guarding are not included in prices

-- safety guarding can be quoted, based on specific information

-

Specifications

| Manufacturer | F&P |

| Model | "Combo" Lines (New), 1500x2mm/5ton #4945 |

| Condition | New |

| Stock Number | 4916083 |