F&P Drywall Profile Lines / 2012-2020 #3576

F&P Drywall Profile Lines / 2012-2020 #3576

Description

< Videos: SEE NEW EQUIPMENT RANGE > #3796, #3996 ETC. / 5.2021 and following

a) 120m / minute Line with no punching operations

b) 60m / minute Line with also punching operations

c) Line End

d) Line - Details

--

Changeover time from a section type to another: 10 minute (with 2 people)

--

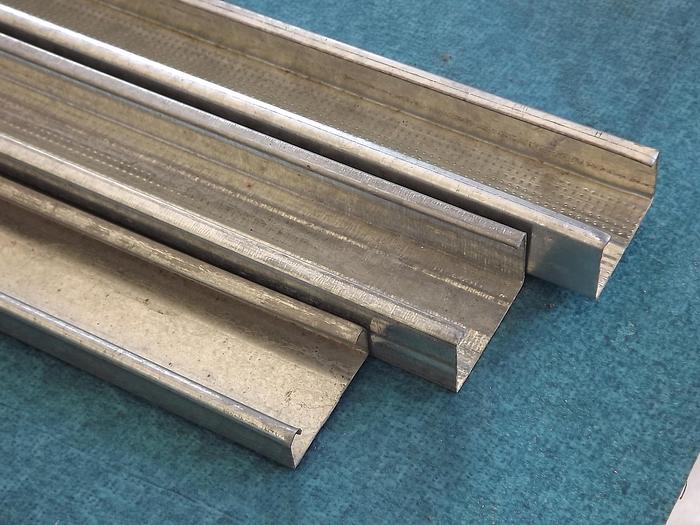

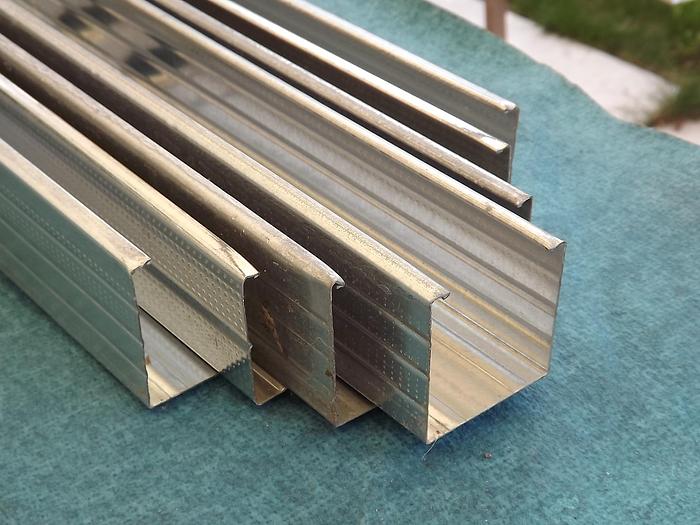

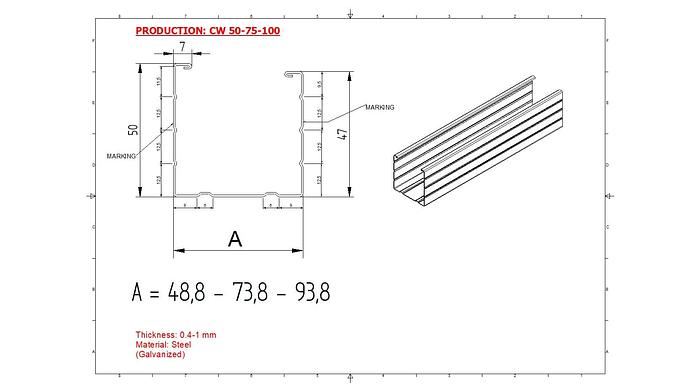

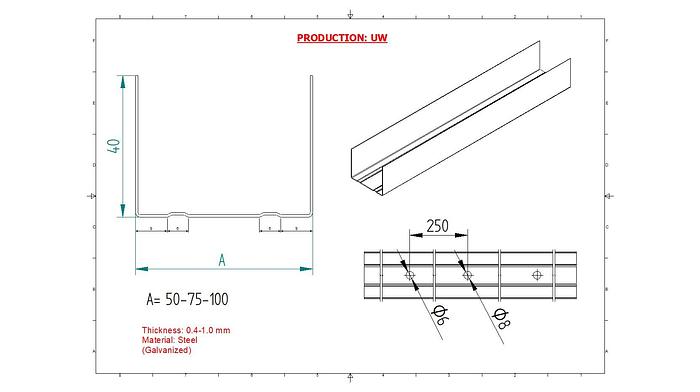

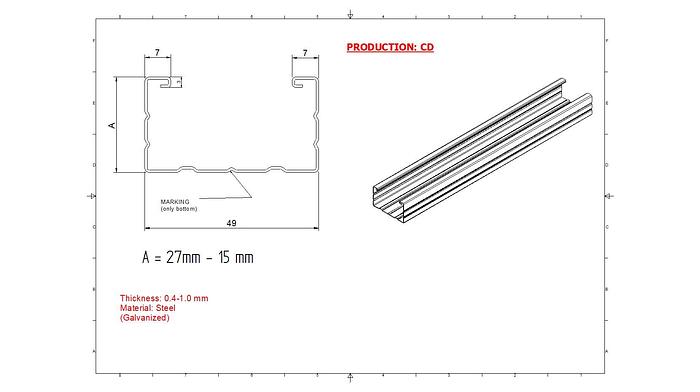

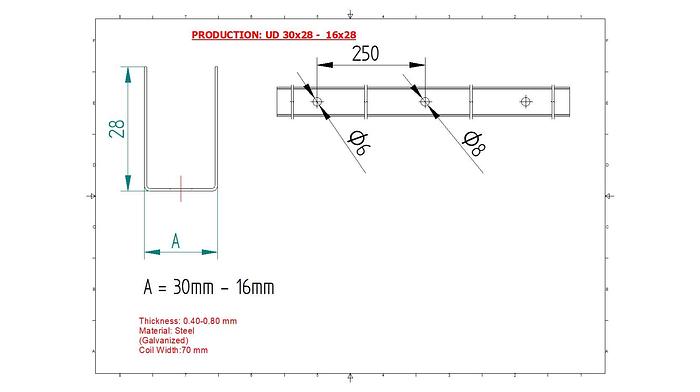

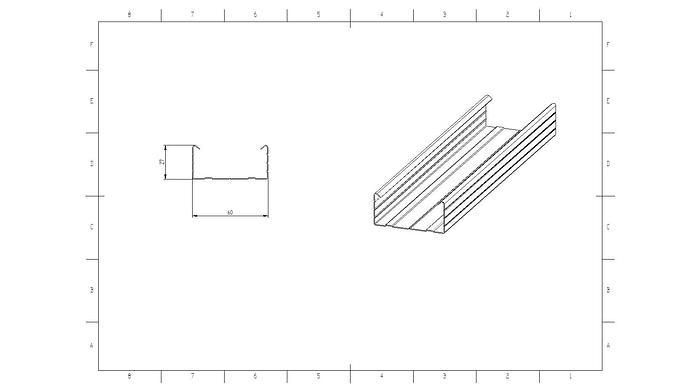

THE PRODUCTS:

- CW 50-75-100 - UW 50- 75 -100 - CD 60x27 - CD 48x27 – 48x15 - U 28x30 – 27x17

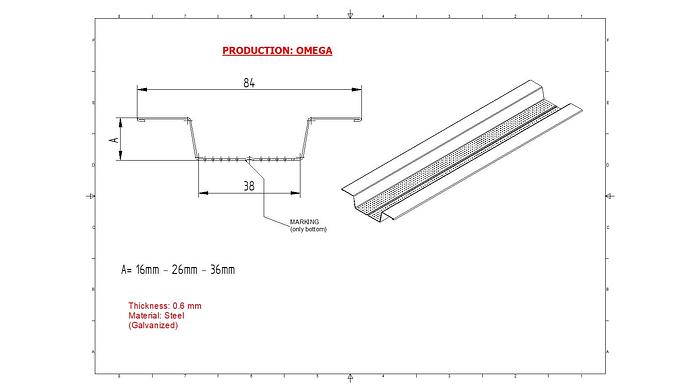

+ MOST COMMONLY REQUIRED OTHER SECTION TYPES (options) : - CORNERS and - OMEGAS

AS PER LAST TWO DRAWINGS BESIDE

--

THE LINE:

[ > please see line dimensions in Attach. (at the bottom) ]

● Normal production speed: 60m / minute * ( * with no holes on sections )

● Material: galvanized steel, .5mm to 1.0mm thick

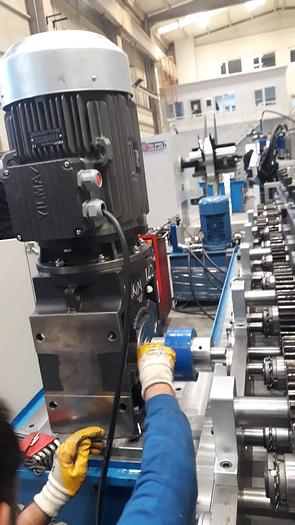

● Installed power :15kW

● Manning level: 2 people

1) DECOILER

Undriven

Coil Width: 300mm max.

1400mm the coil outside diameter

Weight capacity: 2500kg

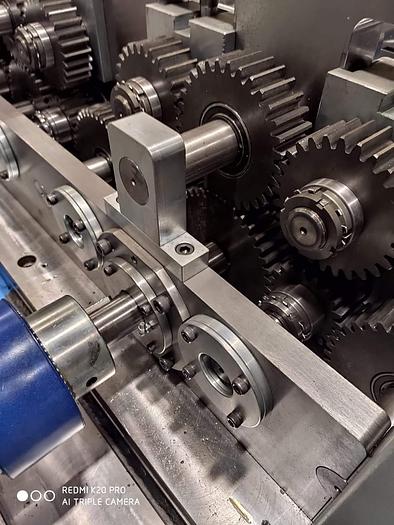

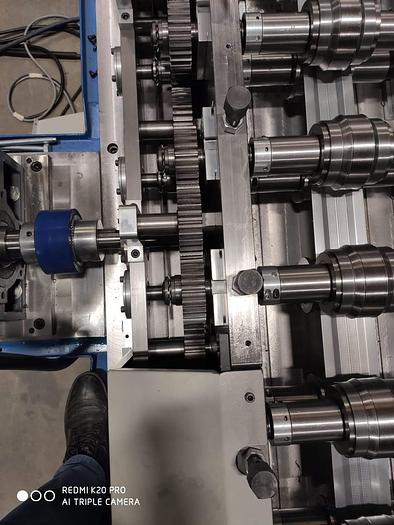

2) ROLLFORMER

Type: RAFTED ( = with 'CASSETTES' )

14-station

Allsteel construction

Machine complete with profile lubrication & cooling system

RAFTS: 5 Sets as below-specified

Roll space 300mm

Shaft dia. 45mm

Adjustable stands (: on operator side) and fixed stands (: on machine-drive side)

-- SAFETY GUARDING to CE

Raft #1 for CW 50-75-100 profile

Number of stations: 14

Raft #2 for UW 50-75-100 profile

Number of stations: 10

Raft #3 for CD 48x27 48x15 profile

Number of stations: 14

Raft #4 for CD 60x27profile

Number of stations: 14

Raft #5 for U 28x30x28 – 28x16x28 profile

Number of stations: 8

Steel shafts arbors hardened and ground, supported on both ends.

The upper arbors are adjustable, to allow adapting the forming rolls to the material thickness

Material of shafts: 4140 alloy steel

The lower and upper shafts are connected to each other by pairs of gears

Bearings: SKF/FAG/TIMKEN

3) FLYING SHEAR

Shear carriage on slides

Shear motion driven by a servo geared motor

Hydraulic power cutoff unit

Cutting dies of tool steel, hardened to 60-62 HRC

Punching units for dia. 32mm holes, positioned at 250mm from the cutoff point; on both profile sides

4) PROFILE OFF-LOAD TABLE

air operated

5) AUTOMATION SYSTEM

● SIEMENS PLC System

● Data input -- product length and quantity

● Infinitely adjustable line production speed

● Electrical components by Siemens/Moeller

● Emergency stop pushbutton ALL TOOLING ^ inclusive SAFETY GUARDING to CE

● Controls: by SIEMENS

● Pneumatics: by FESTO/PAKKENS

● Bearings: by SKF/FAG/TIMKEN

● Tool steels: by ASSAB UDDEHOLM

● Paints: by AKZO

--

for the product packaging systems:

> A https://www.coilandstripequipment.com/listings/124646-drywall-profile-packaging-system-a-new-3517

> B https://www.coilandstripequipment.com/listings/145040-drywall-profile-packaging-system-b-new-3522

(please click on links^)

--

Specifications

| Manufacturer | F&P |

| Model | Drywall Profile Lines / 2012-2020 #3576 |

| Condition | New |

| Stock Number | 454272 |