F&P 1550x.5-2mm Sheet Leveler (New) #4912

F&P 1550x.5-2mm Sheet Leveler (New) #4912

Description

6-HI Type

For: Cold Rolled Steel, Stainless, Aluminium

Tensile strength max: 500 N/mm2

Yield strength max.: 355 N/mm2

Max elongation: 20%

Introduction speed m/min.: 0 - 5

Max workspeed m/min.: 0 - 10

Distance between housings: 1700mm

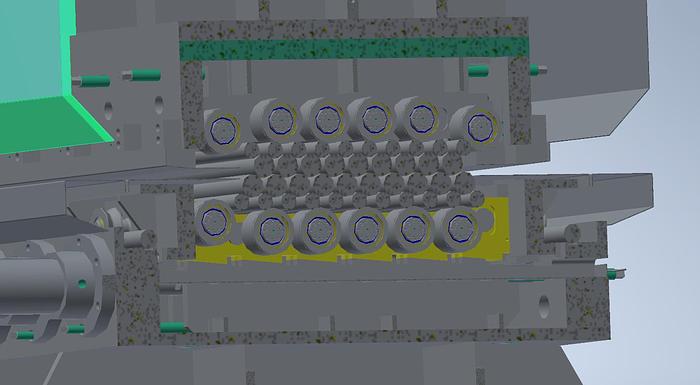

Number of work rolls: 21

Work roll dia.: 36mm

Back-ups: 7 sets, w. digital display -- their positions visualized on PC

The rolls are of special chromium-nickel alloy, hardened to Rockwell 63 C with a soft inner core to allow for roll deflection; ground to mirror-finish, mounted on precision needle bearings

The back-ups, all adjustable provide the necessary deflection to correct material shape. They are moved by hydraulic wedges with visualized position on PC video screen, built-in into consolle with joystick control. Come with precision spherical roller bearings which pivot to conform to the roll face, so as not to mark rolls and provide maximum force

Tilting: 4-way, w. digital display

-- by hydraulic cylinder right to left, raise and lower by hydraulic motor one on each side, operated independently or simultaneously

This is through an electric magnetic clutch, coupled to each side; also providing front-to-back tilt

All controls visualized on video screen, in the front control panel

Leveling pressure is assured by four screws controlled by a worms-and-wormwheel system. It is possible to operate the leveler with the necessary pressure according to the material thickness and to have, at same time, a very positive overload protection. -- The leveler is timed with all other units to ensure having enough material available

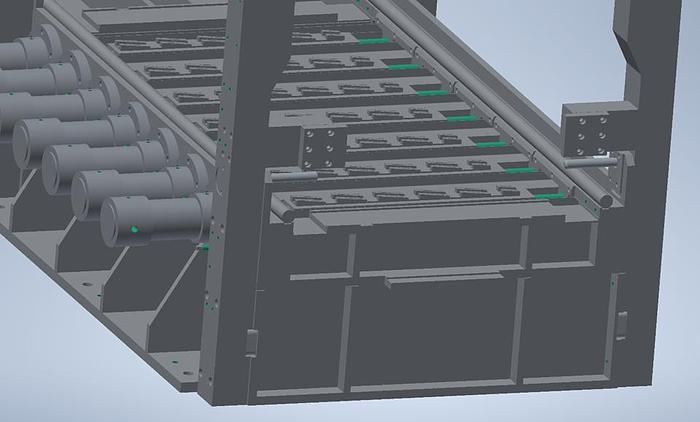

The gearbox is of 3-chamber design. The first chamber is for the first five rolls, which do most of the work and are of the heaviest design. The second and third chamber are of lesser size -due to smaller amount of work to be performed- giving a trouble-free operation

Hydraulic power is from a central source mounted on leveller

Precision measuring rolls are provided at exit of the leveler. The bottom roll is fixed. The top roll is on an air cylinder, adjustable for the pressure; it is mounted on precision bearings, with an encoder mounted outboard

> We suggest to fit at entry of the Leveller pinch rolls coated with special rubber, having dia. 240mm and driven by hydraulic motor and idle wheel on top; mounted on 2 guideways controlled by 2 hydraulic cylinders in order to facilitate the cleaning of the leveler rolls

-

During operation, the leveler is under constant tensioning: therefore the anchoring bolts as well as drives are duly studied and designed to sopport severe working conditions

No noises or vibrations during the material processing: drive is through helical gears running in oil bath, assuring smooth and silent functionning.

The leveler is composed, mainly of two parts:

- the bottom part which is anchored to the floor

- the top part which is movable up and down, as well as tiltable front to back and left to right -- or vice-versa

On the fixed bottom part the following are located:

- the D.C. motor

- the gearbox of 3-chamber design

- the cardan joints

- the lower work rolls

- the “ intermediate rolls

- the “ back-up rolls

- the columns and traverse

- the hydraulic control for the top part of machine

The mobile top part is composed of of a movable structure which contain the other set of work rolls, intermediate rolls and back-up rolls, being same as for the bottom part

On the machine there are 4 types of operations possible:

- opening and closing of the leveling-block

- inclining the leveler top part from front to back and vice-versa

- inclining the same part from right to left and vice-versa

- to adjusting the pushing-pressure of back-ups

The top vertical movements as well the inclination front to back or vice-versa are through two hydraulic motors coupled with an electro-magnetic joint

The longitudinal inclination of the top set of rolls is through a brake-motor, which lets rotate the whole rolls block around its cross axis;

Then the possibility to adjust the pressure of the back- ups: these provide the needed deflection to correct the material shape. The top rows of the back-ups are fixed, so as to be perfectly flat; the bottom back-ups are moved by hydraulic wedges and their positions visualized on the video screen, on the main consolle with joy stick control

The bottom back-ups have precision sphericalroller bearings which pivot to conform the roll face, so as not to mark rolls and provide maximum force

All values reached through the varius adjustmets are controlled by special potentiometers located of the bottom part of the rolls block.

They are readable on video screen of the PC, on the control desk

The adjustment of the bottom roll to correct the material defects are through hydraulic cylinders controlled by the operator

For the top rolls this type of adjustment is done by us during the assembling of the leveller, and the rolls grinding. It is performed manually, through an adjustable screw. Adjustment has a precision of .01 mm (.0004")

The top traverse is connected to the base through four big screws (2 by 2). On traverse top a torsion bar is moounted, splitted in two parts and connected through an electro-magnetic clutch which allows indipendent drive of each couple of screws

The torsion bar is motorized by means of two hydraulic motors which can operate separately or simultaneously. Tilting front-to-back is possible only when the torsion bar is disconnected, while the left-right tilting is obtained through an eccentric systrem controlled by an electric motor.

Values of these tiltings ^ are visualized on PC

The rolls-drive is AC, via gearbox

A set of cardan jointes are running under cascade lubrication and connected to the rolls through spherical joints

Three-phase tension: 380 V 50 Hz + ground

Auxiliary tension: 220 V 50 Hz

Electro-valve tension: 24 V 50 Hz

Hydraulic unit

Pressure of nominal operation: from 100 to 105 bars

Pneumatics

Pressure of nominal operation: 6 bars

-

-

Specifications

| Manufacturer | F&P |

| Model | 1550x.5-2mm Sheet Leveler (New) #4912 |

| Condition | New |

| Stock Number | 4707271 |