F&P 12mm CTL Lines (New) #3395

F&P 12mm CTL Lines (New) #3395

Description

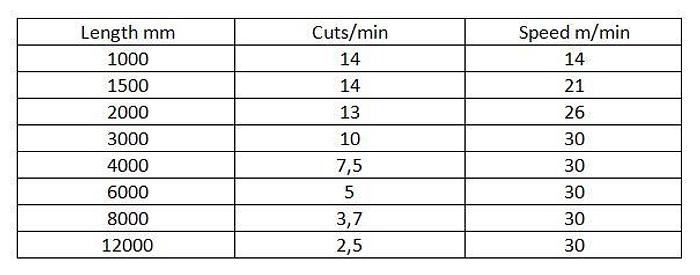

New Flying Shear Cut To Length Lines 2100mm x 12mm HR, Galv., Pickled Steel CUSTOM DESIGNED -- 12m / 10 Tonne Sheet Stacker Speed max. 30m / min -- The process material -dry or oiled- is: galvanized, pickled steel with R = max. 800 N/mm², up to 10mm thick; yield strength max. 500 N/mm² up to 12mm thickness The minimum material thickness is 1.5mm; minimum coil width: 600mm Coil OD: 1000mm to max. 2300mm The Coil ID is 508*-610-760mm (*coil weight max. 25 Tonne) The cut length is 1-12m Max. sheet stack height 500mm, max. weight 10 Tonne (max. 2 Tonne per-meter) Tolerance on sheet diagonals: ± 2mm up to a 2m length Cut length accuracy: ± 1mm The material threading speed is 10m / min Passline height: ca. 1300mm -- EQUIPMENT LIST : 1) ENTRY COIL RAMP 2) MOBILE, DOUBLE OPPOSED MANDREL TYPE DECOILER 3) COIL THREADING STATION WITH HOLD-DOWN ROLL, OPENING TABLE AND ELECTRONIC CENTERING SYSTEM 4) STRAIGHTENER 4.1) HYDRAULIC CROP SHEAR & SCRAP COLLECTION BOX 4.2) OPTION: "ROUGH-OUT" BRUSHING MACHINE 4.3) OPTION: SUCTION SYSTEM 5) INTERMEDIATE TABLE WITH VERTICAL ROLL CENTERING STATION 6) HEAVIER GAUGE LEVELLER 6.1) OPTION: "FINISH" BRUSHING MACHINE #1 6.2) OPTION: SUCTION SYSTEM 7) LIGHTER GAUGE LEVELLER 7.1) OPTION: "FINISH" BRUSHING MACHINE #2 8) FLYING SHEAR 9) SHEAR CONVEYOR-BELT 10) TRANSFER BELTS & DEFECTIVE SHEETS EVACUATION AREA 11) SHEET STACKER 12) TRANSFER CHAIN TABLES AND WEIGHING SYSTEM 13) ELECTRICS & ELECTRONICS 14) HYDRAULICS 15) PNEUMATICS 16) PERIMETER GUARDING -- ^ DETAILS : 1) ENTRY COIL RAMP The Two-Station Entry Coil Ramp has a ca. 6m horizontal stroke and, 800mm up/down-stroke. It is hydraulically operated. 2) MOBILE, DOUBLE OPPOSED MANDREL TYPE DECOILER The decoiler can handle these minimum material widths: with ø 508mm > min. 600mm with ø 610mm > min. 600mm with ø 760mm > min. 700mm With two very robust, sliding allsteel basements and AC motor driven it has two 3-step expanding / collapsing mandrels. After the material threading phase, the motor works as generator-brake during the line operation: a pre-fixed 'pull' action by the operator remains constant, while the coil diameter and line speed vary. The positioning of the mandrels is hydraulically operated. A stand-by brake is provided for the decoiler. 3) COIL THREADING STATION WITH HOLD-DOWN ROLL, OPENING TABLE AND ELECTRONIC CENTERING SYSTEM Gantry type, it has auto. edge guide by photo-electric cell (5mm readout accuracy). 4) STRAIGHTENER It has 5 + 1 work + corrective rolls (dia.: 180mm) and 2 pinch rolls (dia.: 300mm). The two upper work rolls and the exit corrective roll are electrically adjustable. AC motor drive, helix gears and pinions in quality alloy steel, universal joints for the work rolls. 4.1) HYDRAULIC CROP SHEAR & SCRAP COLLECTION BOX (For the coil leading edge & "tail") The scrap collection box is mounted on rails and can be extracted on operator's side. The scrap max. length is 1000mm. 4.2) OPTION: "ROUGH-OUT" BRUSHING MACHINE It is for both the upper and lower coil faces. The AC motor driven brushing machine is mounted on a mobile base, whose position is controlled by encoder. 4.3) OPTION: SUCTION SYSTEM - like the 6.2 herebelow 5) INTERMEDIATE TABLE WITH VERTICAL ROLL CENTERING STATION With 4 undriven rolls (dia.: 160mm), self-centering, is hydraulically operated and ca. 2m long. The table exit section is hinged to allow access to leveller [ > 6) ]. 6) HEAVIER GAUGE LEVELLER With 13 work rolls (dia.: 160mm) and 5+5 sets of back-ups (dia.: 200mm), it is for levelling 4-12mm thick material. 7 work rolls are mounted on the leveller lower section, 6 on upper tilting section. The lower back-ups are mounted on steel supports, sliding on mechanical jacks that are operated by hydraulic geared motors; the upper back-ups are adjustable by wedges. The strokes are shown on the control panel. 6.1) OPTION: "FINISH" BRUSHING MACHINE #1 It has same general features as the 4.2)^. 6.2) OPTION: SUCTION SYSTEM for the calamine dust With filter, hoppers, washing and cleaning system, 36.000 m3/hour fan, chimney, piping etc. 7) LIGHTER GAUGE LEVELLER With 17 work rolls (dia.: 70mm) and 7+7 sets of back-ups (dia.: 120mm), it is for levelling 1.5-4mm thick material. 9 work rolls are mounted on the leveller lower section, 8 on upper tilting section. The lower back-ups are mounted on steel supports, sliding on mechanical jacks that are operated by hydraulic geared motors; the upper back-ups are adjustable by wedges. The strokes are shown on the control panel. 7.1) OPTION: "FINISH" BRUSHING MACHINE #2 It has same general features as the 4.2)^. 8) FLYING SHEAR Of mechanical power type with geared motor and inverter, it runs on ball recirculation pads. The shear parts lubrication is automatic. Cutting Frequency & Speed Chart: please see under "PHOTOS & IMAGES" beside 9) SHEAR CONVEYOR-BELT Drive: AC motor and inverter. 10) TRANSFER BELTS & DEFECTIVE SHEETS EVACUATION AREA Drive: AC motor and inverter. In PVC with pinch rolls, inclinable chute and powered collection cart on rails for defective sheets (max. 3m long / max. 2 Tonne) 11) SHEET STACKER For 1-12m long sheets, with a 10 Tonne max. capacity, has side and front/back joggers and two programmable hydraulic lifting tables. 12) TRANSFER CHAIN TABLES AND WEIGHING SYSTEM ca. 6.5+6.5m long x 2 tables, with max. capacity 6 + 6 Tonne (2.5 Tonne per-meter). AC motor drive with inverter. 13) ELECTRICS & ELECTRONICS SIEMENS S7 PLC & AC motors; electric cubicles, control panels etc. 14) HYDRAULICS With 1000 litre tank; max. pressure: 120 bar. Heat exchangers, 24 V electrovalves etc. 15) PNEUMATICS With filter-lubricator units, regulator & pressure gauge, silencers. Pressure: 6 kg/cm2. 16) PERIMETER GUARDING The line safety guarding is complete with interlocks and photo-electric cells.

-

Specifications

| Manufacturer | F&P |

| Model | 12mm CTL Lines (New) #3395 |

| Condition | New |

| Stock Number | 70057 |

| Reference number | 3395 |