F&P Custom Sheet Metal Handling System (New) #3702

F&P Custom Sheet Metal Handling System (New) #3702

Description

- also for light gauge material; always built to specification

this example:

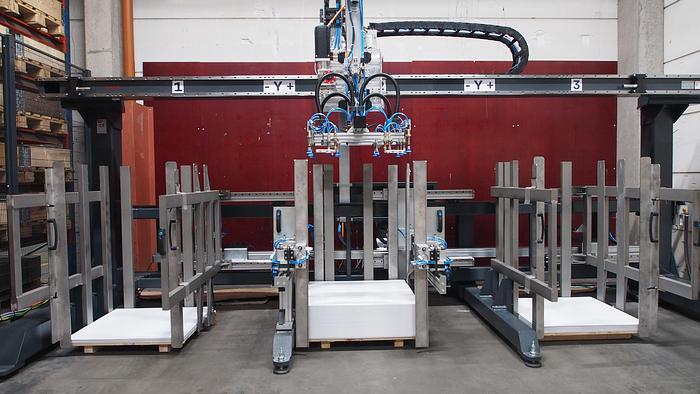

three-station stacking/destacking system

in which the blanks are taken from the two side stations, then dropped and aligned on the central station. The side stations are equipped with passive adjustable containers, to keep the blank stacks aligned during the separation process: adapting to the different sizes of the blanks. The central station is also equipped with adjustable containers, on which active locators keep the dropped-off blank aligned with the stack itself

- blank length x width: minimum 500mm x 700mm, maximum 1000mm x 1200mm

- material thicknesses: minimum .12mm, maximum .5mm

- materials: steel, magnetic or austenitic; aluminium

- blank weights: minimum 180gr, maximum 3.8kg

- stack height: maximum 1.150mm

- stack weight: maximum 3.500kg

- average cycle time: 6 seconds ( =10 parts/minute )

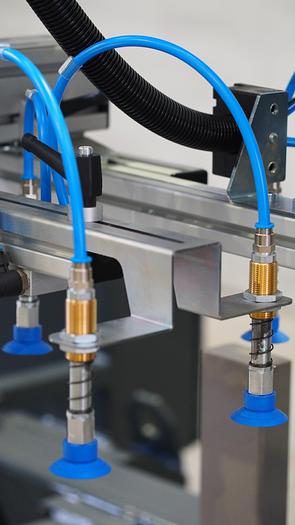

The handling of the blanks is managed by a two brushless axis gantry-type manipulator. An adjustable gripper with vacuum caps ensures the lifting and transfer of the blanks; the separation is done by slightly flexing the edges of these.

We design and build sheet metal handling systems, also robotic, to sheet metal machinery builders as well ***

--

-

Specifications

| Manufacturer | F&P |

| Model | Custom Sheet Metal Handling System (New) #3702 |

| Condition | New |

| Stock Number | 774317 |