F&P Coil Punching Lines (New), "Standard" #3485

F&P Coil Punching Lines (New), "Standard" #3485

Description

THIS TYPE OF EQUIPMENT IS NO LONGER BUILT

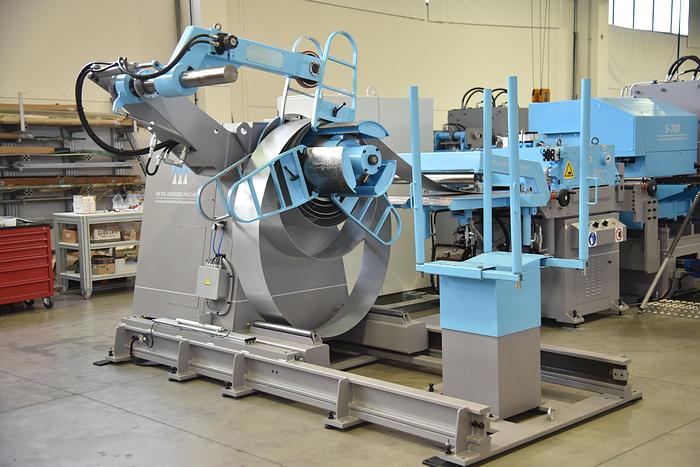

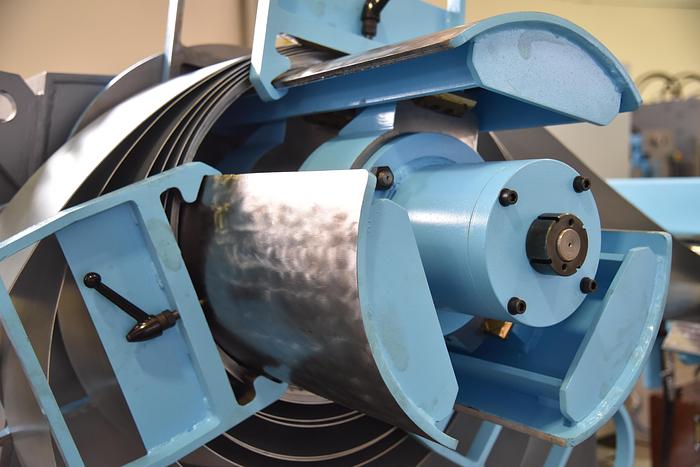

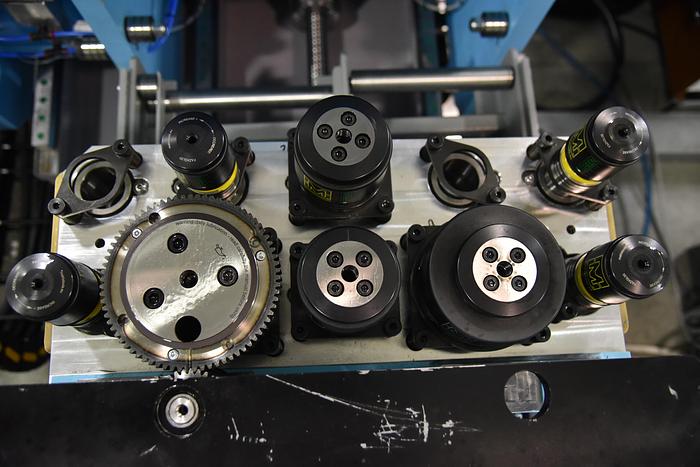

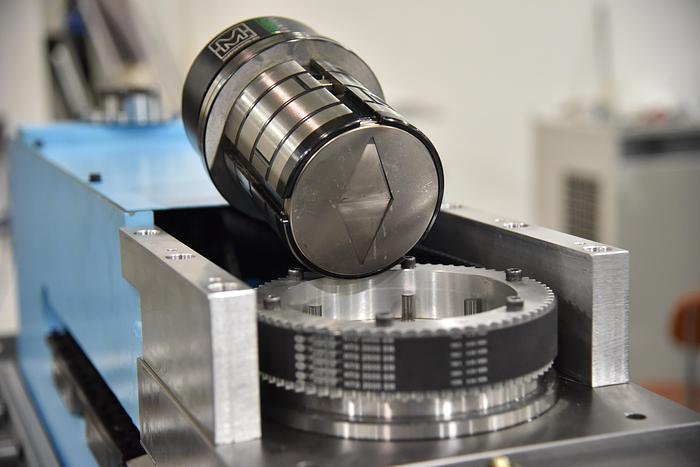

Heavy Duty Coil Punching & Stamping Lines 650mm x .7-6.0mm(8.0mm Alu.) Max. Feed Speed: 45m / min -- Accept: Mate, Matrix, Wilson... all 'thick turret' tooling from the market -- Description: [* = different features on demand] 6 T* Decoiler Coil ID 470-550mm* Coil OD max. 1600mm* Hydraulic drum expansion Powered, hydraulic strip hold-down Loop control by mass contact & ultrasounds Coil Car 2+9 Roll* Straightener-Feeder with hydraulic, telescoping Entry Table Diameter of Work Rolls: 100mm* Opening Upper Section of Frame, to allow easier cleaning of rolls Multi-Head Punching Station (capable of 1.5 hits/minute; with 12mm daylight on Units) with: -6 x 12 T*/each cylinders -2 x 20 T*/each cylinders -2 x 30 T*/each cylinders -- Extractable Unit with: -6 x punches with max. dia. 31.2mm (B Stations)* -2 x punches with max. dia. 50.8mm (C Stations)* -1 x punch with max. dia. 88.9mm (D Station)* -1 x Multi-Tool with max. dia. 88.9mm (D Station)* -- Extractable Unit with: -1 x 45 T cylinder* -1 x Index Tool with max. dia. 88.9mm (D Station)* -- Proportional Hydraulics ^ Scrap Collection Belts Hydraulic Marking Unit Hydraulic Press with 2 independent cylinders, 75 T*/each (75mm the cylinder stroke) with: -central Material Guide -transversal machine stroke +/-100mm* (motion by brushless motors) -vertical positioning accuracy ensured by linear transducers -860mm x 1200mm* work area for stamping operations -- Proportional Hydraulics ^ Scrap Collection Belts Hydraulic Shearing Station with manual knife clearance adjustment Parts Extractor Auto. Stacking System (Option) normally for parts with max. dims.: 650mm x 5100mm x 450mm in height* - mounted on wheels* (Material Guides: manually-adjustable standard, powered optional) Siemens 840 D CNC with mobile control panel Centralized Lubrication System CAD/CAM Peripheral Safety Guarding -- "Standard" paint colours: RAL 5017, and RAL 9003 (the mobile parts)* -- Average coil change + adjustments time: ca. 15 minute Average complete tooling change time: ca. 20 minute / ca. 5 minute with an extra die holding plate (option) [the punches do not require clamping -- thus changing them is a very quick operation] Average shear-knife clearance adjustment time: ca. 1 minute

-

Specifications

| Manufacturer | F&P |

| Model | Coil Punching Lines (New), "Standard" #3485 |

| Condition | New |